"*" indicates required fields

When it comes to storing chemicals, West Coast Poly’s chemical storage tanks are your solution.

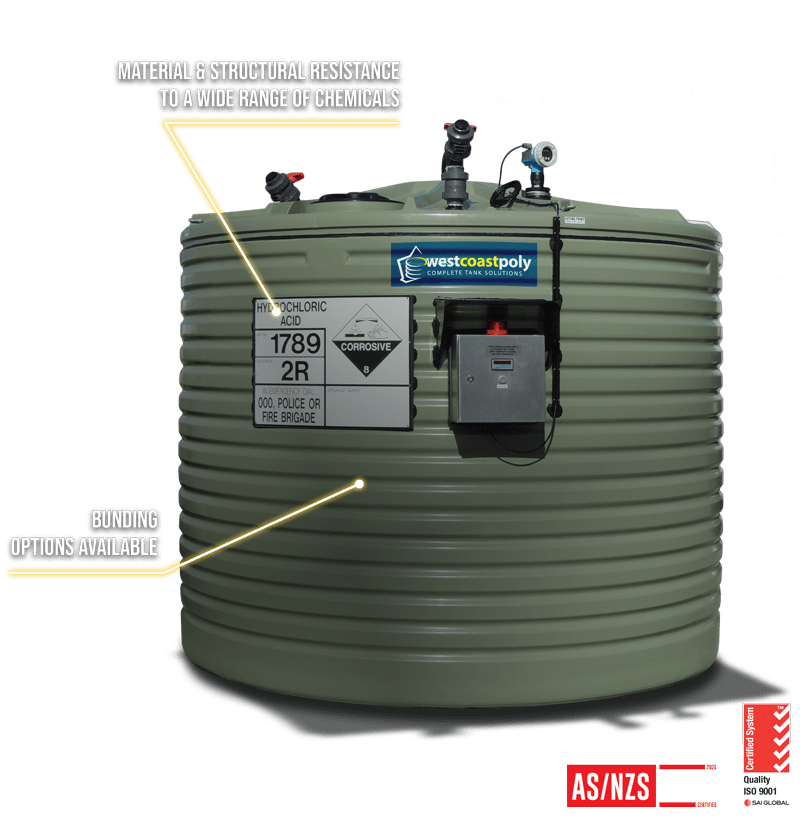

Designed and constructed for exceptional resistance to a wide range of chemicals and as well as being resistant to inorganic acids, alkalis and aqueous solutions.

Custom built to your requirements by our team of technicians. We take into account the most finite of details, when it comes to designing your chemical tank.

We can construct our chemical tanks within a wide range of high specific gravity. So that your tank is ideally suited to the chemicals you are needing to store securely at your facility or site. For safe, secure chemical storage, our chemical tanks also have bunding options available, from fully contained storage units or open bunded units.

Our team are there to assist in every aspect of your project journey from the technical drawings to the precision placement of fittings, to the timely delivery and set up on site. If you would like to know more, simply contact our friendly team.

Read more of our case studies on all our Industrial and Mining Products

West Coast Poly’s chemical storage tanks are engineered with precision to provide optimal containment solutions, offering both self-contained bunds and open bunds tailored to meet diverse industrial needs.

Our self-contained bunds – are integrated directly into the tank design, ensuring a secure and reliable barrier against leaks or spills. These bunds provide an added layer of protection, effectively containing any potential chemical runoff.

Our open bunds – offer versatility and accessibility, allowing for visual inspection and easy maintenance. With West Coast Poly’s chemical storage tanks, you can confidently choose between these bund options, knowing that each is designed to enhance the safety and compliance of your chemical storage while accommodating your operational requirements seamlessly.

West Coast Poly takes pride in offering customisable solutions for your chemical storage needs. Including the ability to tailor the poly material in our Chemical Storage Tanks to effectively handle liquids with high specific gravity.

Our engineering expertise allows us to modify the material composition, reinforcing it to withstand the increased weight and pressure exerted by heavy liquids. By enhancing the polyethylene material, we ensure that our tanks maintain their structural integrity and prevent deformation or compromise. Even when storing liquids with high specific gravity.

This advanced customisation ensures that your chemical storage process remains safe, reliable, and compliant, while providing the flexibility to accommodate a wide range of substances within our durable and adaptable tanks.

West Coast Poly tanks are manufactured to cope with the harsh West Australian environment and are suitable for external installation. West Coast Poly uses a material which has a UV performance level of UV 20 which is more than the Australian standard requirement. This material is standard for our storage tank range so that customers can be assured they are getting the highest UV protection available.

LMDPE – a hexene grade co-polymer based linear medium density polyethylene. The material offers excellent impact strength and long-term UV stabilisation it is suitable for manufacturing a wide range of products.

HDPE – A new generation of Hexene HDPE, principally for chemical storage tank applications. Suited for manufacturing large storage tanks, the advanced technology of the material leads to superior mechanical properties, high impact strength, high stiffness and long-term UV stabilisation.

You can learn more about our materials here

Our tanks are a seamless single piece construction making them tough, durable & long lasting in even the harshest condition. We achieve this by using state-of-the-art machines and techniques at our manufacturing facility in Canning Vale WA. Cutting edge computer systems enable us to monitor the internal temperature, rotations and cook times. Ensuring each tank produced is of the highest quality. You can learn more about our manufacturing process here

Our quality assurance team conducts rigorous and thorough testing on each tank, making sure every tank meets our precise quality specification. Through means of impact testing, ultrasound testing and hydrostatic temperature.

Impact Testing: To ensure the performance & workmanship of each finished tank, a member of our quality assurance team cut samples from a tank after it is made and freezes them. Once the samples have reached -40c we use a drop dart to evaluate impact strength & toughness, ensuring the vessel meets our quality standards.

Ultrasonic Testing: To ensure an even and thick tank structure, our quality assurance team use precise ultrasound equipment, anywhere on the tank walls, roof or floor. This specialised technique allows us to measure the thickness profile of the tank & make sure it’s the exact thickness to meet our quality specification & standards.

Hydrostatic Load Testing: If the tanks have specialised fittings, our quality assurance team can conduct pressure and leak testing, ensuring your tank is fit for purpose when it arrives at site.

Lifting Load Point Test: Testing conducted to achieve certification on the tank lifting points to the working load limit.

In keeping with the high-quality standards applied to manufacturing, West Coast Poly keeps meticulous records of their manufactured products. Standard details of all tanks are recorded with the tanks unique identification number.

West Coast Poly’s manufacturing processes and products are certified to meet these Australian standards:

For additional information, please email your requirements and we will contact you to discuss further

Quality polyethylene storage tanks suitable for a wide range of applications, factory fitted and tailored to your exact requirements.

With our vast experience accumulated over two decades, we will come up with the best and most economical delivery solution.

For more information and details, please see the Delivery Section