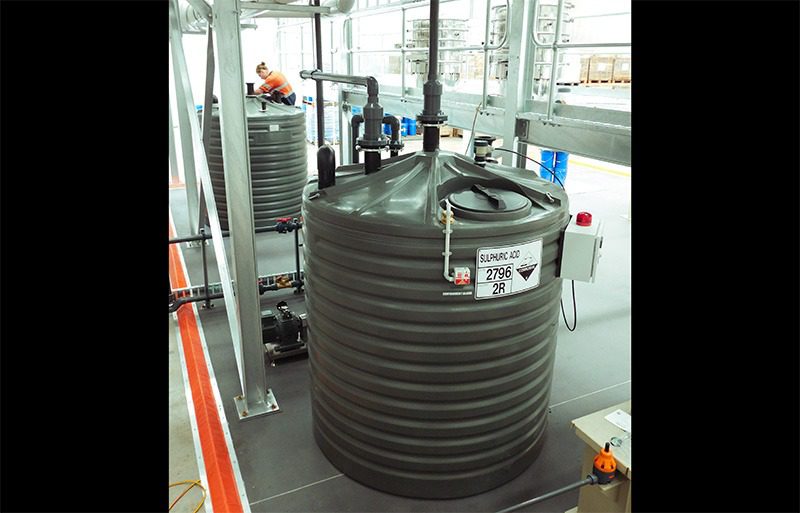

Your perfect tank solution doesn’t exist until we build it.

Because of West Coast Poly’s wide product range, we can offer solutions that suit multiple applications across various industries, while our expert technicians are also able to customise our products as required.

When it comes to designing your tank, our Technical Staff and Engineering team can assist with the design of your project to create the ideal tank to best suit the needs of your operation.

At West Coast Poly, we are not just a provider of solutions, we are partners in progress we will work closely with you to determine what your project goals are and the exact requirements of the tank, guiding your project from concept, to construction, to the final delivery. While we consult specifics on vessel layout and design, we also work closely with material suppliers and engineering teams to determine the correct materials and fittings. To ensure our products will you provide with reliable & scalable solutions, that not only meet your objectives but surpass them.

If you have a project that requires a custom tank solution, contact our technical sales team today, so we can start designing your perfect storage tank.