Reliable insulated tank, making sure you can handle the heat….

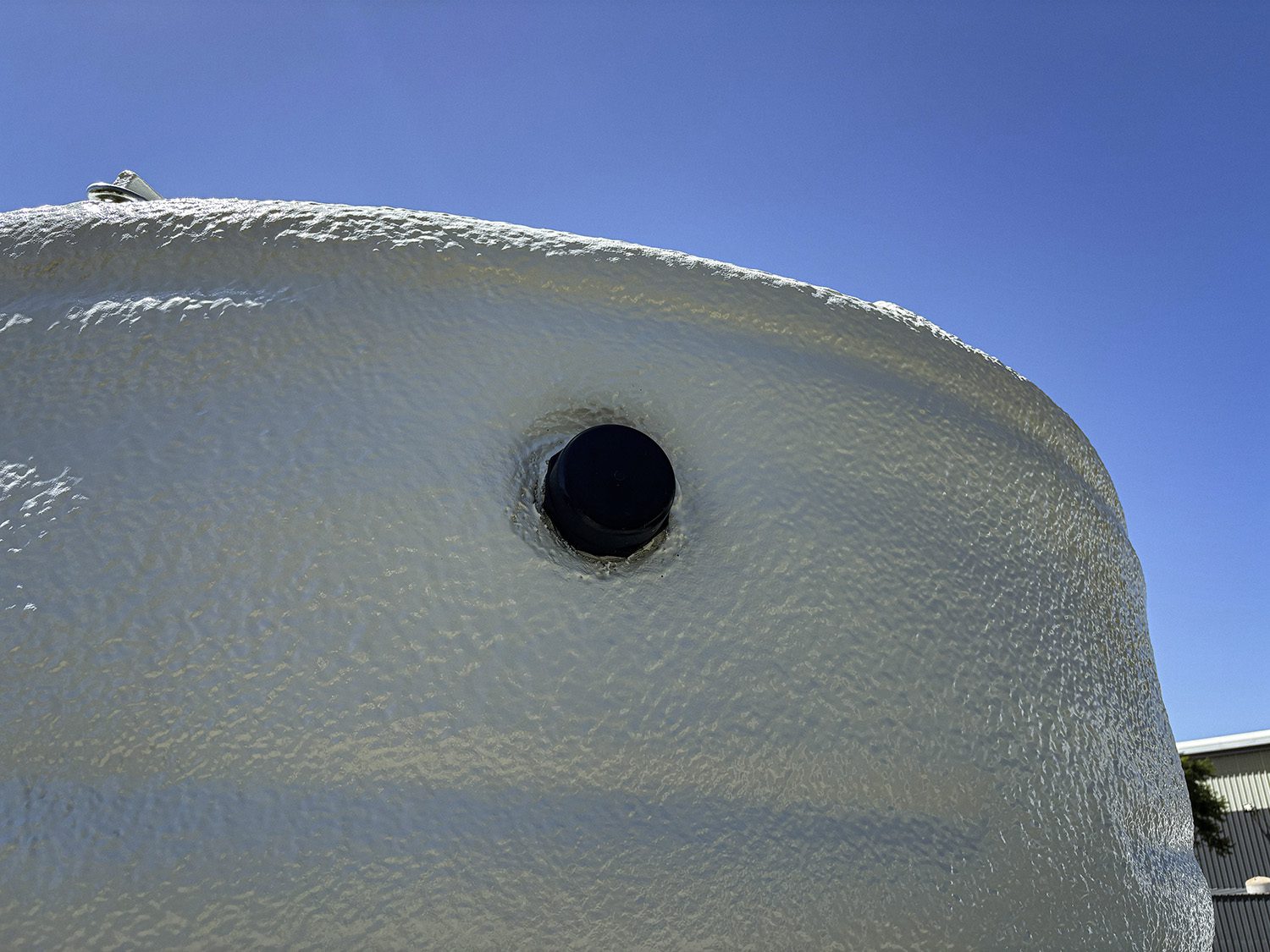

This tank dubbed affectionately by our team “the marshmallow”, is a 10,000L insulated tank that will store process water for machinery cooling. The water stored in the tank needs to be kept at 8 degrees and will be looped through a chiller. Our client’s problem is not an uncommon problem, through the course of the industrial process, a considerable amount of heat is generated by any one machine. Which if left unchecked, can do some considerable damage to machinery.

Process cooling water is a method of utilising chilled water to absorb the heat produced in an engine or a machine. Water is used, because it has a high capacity to absorb heat, making water an excellent cooling agent. In fact the reason water is used over air is because water can conduct heat about 30 times faster.

So for our client, to keep the machines wheels turning, they need to ensure that their cooled water is kept at an 8 degree temperature. Which is where our insulated tank designs can help. Despite the nickname the textured coating is not marshmallow it is a polyurethane foam with an elastomer protective coating technology, which we sprayed on with a 50mm thickness. This forms an impermeable barrier, effectively insulating the poly tank from external temperature extremes including temperature through conduction with ground. By creating an airtight seal, this advanced insulation minimises thermal bridging, maintaining consistent internal temperatures.

The tank is also fitted with 3″ BSP fittings on the two bottom outlets and two returns.

For tank ventilation we used a gooseneck atmospheric vent with vermin stainless steel protection limiting the ingress of contaminants into the tank while also allowing safe vessel ventilation.

For our client this, tank has helped them take charge of temperature control, and ensures their machines will run as smooth as a swiss watch.